Quad-Lock Building Materials

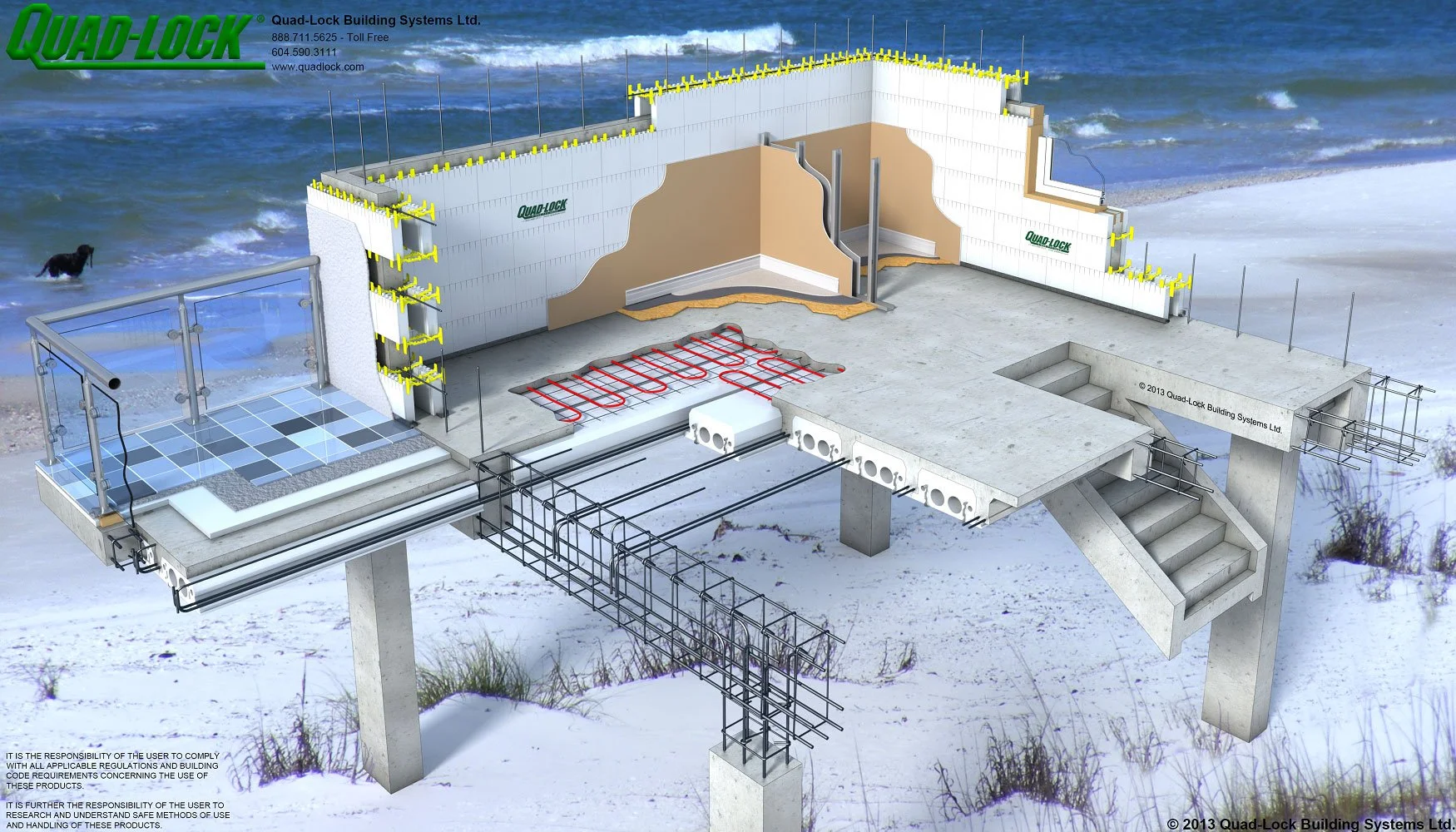

Quad-Lock Insulated Concrete Forms are a flat system using panels and ties (as opposed to block systems). The panel and tie design makes Quad-Lock highly versatile using only standard parts. Quad-Lock can easily be shaped to form all the design elements of modern buildings including openings, arches, corners, any angles, and real curves with almost any radius.

Quad-Lock Walls

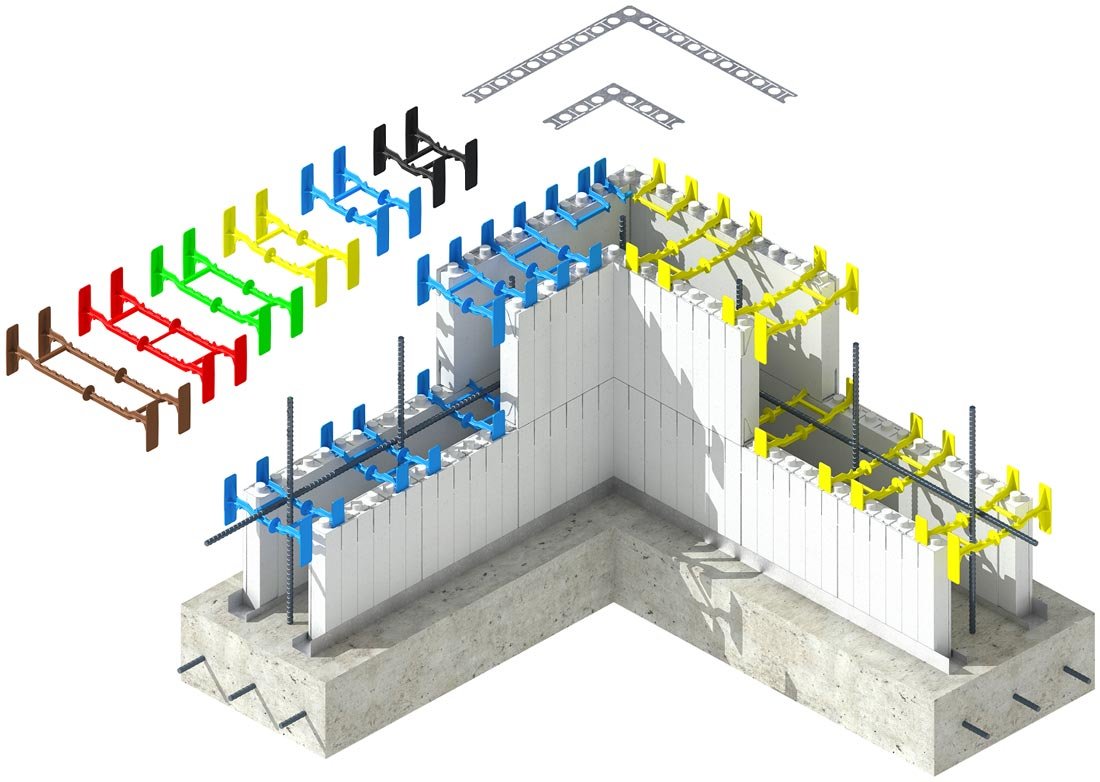

Quad-Lock is a panel type ICF wall system consisting of panels, ties, metal track and metal brackets. Quad-Lock Panels are made with high density, fire retardant expanded polystyrene (EPS) which uses no formaldehyde, HFCs or CFCs. Seven panel types and eight types of plastic ties allow virtually limitless design options using standard components. R-values range from R-22 to R-59 - the highest in the industry.

Plastic ties ingeniously connect the panels and support the reinforcing steel, while also providing a means to anchor drywall, siding and temporary bracing. Metal track is used to start and finish the walls and metal brackets create the strongest corners in the industry eliminating zip-tying or additional outside bracing at corners and angles.

Applications include load bearing walls, shear walls, fire resistant walls, basement walls, retaining walls, and foundation walls incorporated in residential, commercial, and institutional construction.

Build unlimited wall widths, many different insulation values, the strongest ICF corners, angles, T-walls, pilasters, and radius walls, using just a few standard components.

Panels made of Expanded Polystyrene (EPS) and Ties made of High Density Polyethylene (HDPE) create a formwork for concrete plus vertical and horizontal reinforcing steel.

Filling the cavity with concrete creates solid, reinforced concrete walls with 2-4 hour Fire Resistance Ratings (FRR), low maintenance, and outstanding durability and resilience. The Quad-Lock forming system stays in place to provide space to run small utilities, serve as backing for finishes, and incorporate superior, continuous insulation layers. The high insulation values, low air infiltration, and high thermal mass can achieve significant energy savings for building owners, operators, and tenants over the building's longer lifetime.

Quad-Deck Floors & Roofs

Quad-Deck uses patented technology to create an energy efficient and quality insulating concrete floor or roof system. Ideal for use in both commercial and residential construction, Quad-Deck combines the strength, security and reliability of concrete with the energy efficiency, design flexibility and comfort of insulating concrete forms.

Quad-Deck panels shape a series of T-beams every 24" [610mm] which integrate with a concrete slab. The resulting monolithic concrete structure provides two-way span capacity and a shear plane for superior structural performance using less concrete & less time.

Each of the expanded polystyrene (EPS) panels are supported and reinforced with two integral steel beams molded into the product from end to end. The result is a self-supporting joist and deck forming system that provides the maximum strength of a reinforced concrete deck with a minimum of materials and labor.

Quad-Lock Building Systems was established in 1994 to develop and distribute patented Insulating Concrete Forms (ICF). Quad-Lock was then one of the first flat-wall ICF systems and it continued to be the leading innovator with higher insulation values, very wide walls, insertion panels, and an ISO 9001 certified quality management system.